Exciting News! Songu Laser Has Been Awarded the Title of “SME in Specialized New Sectors”

Recently, the Jiangsu Provincial Ministry of Industry and Information Technology released the 2023 list of SMEs in Specialized New Sectors. Songu Laser Technology (Jiangsu) Co., Ltd. was awarded the title of “SMEs in Specialized New Sectors”. This marks another official recognition of Songu laser’s comprehensive strength in specialization, refinement, distinction, and innovation.

“Specialized and New Enterprise” refers to enterprises characterized by “specialization, refinement, distinctiveness, and innovation.” These companies are leaders that focus on market segment, strong innovation ability, high market shares, master key core technologies, and excellent quality and efficiency. It represents the most authoritative and highest-level honor in the national evaluation system for SMEs. Winning the title of “Specialized and New Enterprise” this time fully reflects the high recognition from official institutions and various sectors of society for Songu Laser’s achievements in independent innovation, the research and development outcomes, market value, industry leadership, and potential for future growth.

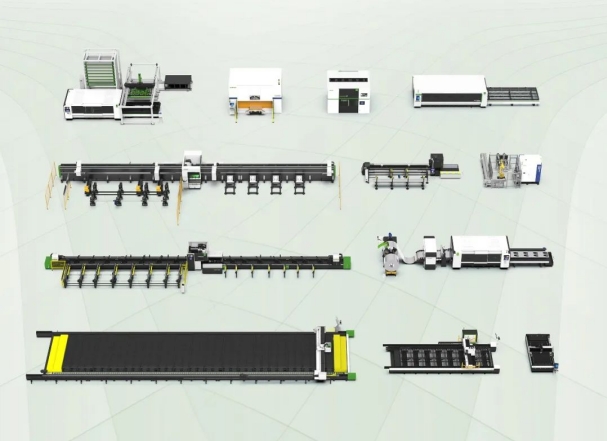

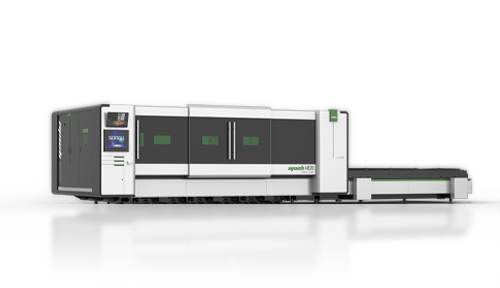

Songu Laser adopts a dual-driven model of research and development and intelligent manufacturing, continuously enhancing innovation, improving quality, and refining management. It provides one-stop laser application solutions for customers in the metal industry, covering a comprehensive product matrix of laser applications for metal processing, including metal sheet laser cutting, metal tube laser cutting, ultra-large format 10,000-watt laser cutting, 3D laser processing workstations, laser welding laser cleaning, automated warehousing, and automated laser applications. Songu Laser is committed to empowering and enhancing efficiency for customers in industries such as automotive manufacturing, shipbuilding, construction machinery, agricultural machinery, sheet metal processing, and steel structures, helping them with transformation and upgrading. Many of its key technologies are comparable with international first-class standards, filling gaps in domestic industry sectors. Songu Laser has become the preferred brand for high-end laser equipment applications in china and a leading option for import substitution.

As a technology-driven intelligent equipment manufacturing enterprise, innovation has always been the primary driving force for Songu Laser’s development. The company has established a laser technology innovation base that unites professional expertise, drives technological leadership, and ensures high--efficiency output. Every year, Songu Laser invests no less than 10% of its sales revenue to research and development, ensuring that the performance and technology of Songu Laser’s equipment remain at the forefront of the industry.

To ensure the high reliability and sustainability of its laser equipment, Songu Laser imported more than 100 sets of high-end industrial processing equipment and precision testing instruments from Japan, Germany, and the United States. These include large gantry CNC machining centres, heat treatment equipment, five-axis machining centres, machine tool coating production lines, as well as two-dimensional measuring devices, dynamic balancing correction instruments, laser instruments, and circularity measuring instruments. Songu Laser has developed a comprehensive and controllable mass production manufacturing capability for large-scale laser equipment, covering the entire process from steel cutting, welding, heat treatment, machining, and surface coating to complete machine assembly and commissioning. With and annual production and sales volume of over 10,000 units. The company has reached industry-leading levels in the speed of R&D results conversion, technological updates and iterations, order delivery capabilities and quality control. Songu Laser is now on a fast track to high-quality development.

In addition, Songu laser has taken the lead in implementing advanced international modular manufacturing projects. By advancing through two pathways, modular design and modular manufacturing, the company has broken away from the traditional linear production processes, focusing more on parallel and integrated workflows. This has doubled production efficiency and achieved a delivery completion rate of 99.6%, resulting in simultaneous improvements in both efficiency and quality. This allows Songu Laser to adapt to rapidly evolving market changes and customer demands.

Songu Laser will take this recognition as a new starting point, closely following the pace of the times, and continue advancing along the path of specialization, refinement, distinctiveness, and innovation. The company will accelerate independent innovation in the field of laser equipment manufacturing, continuously enhance its technological research and development capabilities, and innovation potential. It will also fully leverage the power of laser technology to drive intelligent manufacturing, contributing to the optimization and upgrading of the industrial structure within specialized and innovative sectors of the manufacturing industry.

Related news

-

Wang Jianfeng, Deputy Secretary of the Xuzhou Municipal Party Committee and Mayor, visited Songu Las

2024-09-19 16:20:14

-

Strengthening Quality Development and Fortifying the Great Wall of Quality: Songu Laser’s 2024 Quali

2024-09-19 16:20:14

-

Songu Laser’s Taicang Factory Relocation Marks a Significant Milestone in Strategic Growth

2024-09-19 16:20:14

Spanish

Spanish Portuguese

Portuguese