Songu Laser’s Taicang Factory Relocation Marks a Significant Milestone in Strategic Growth

Note:

Amid the extreme involution of China’s laser equipment manufacturing industry, and to ensure that every piece of laser equipment produced by Songu Laser fully meets the quality standards required for export to Europe, the United States, Japan, Korea, and other countries, Songu Laser Technology (Jiangsu) Co., Ltd. officially launched the second-phase expansion project of its production base in Xuzhou, Jiangsu Province, in July 2021. includes the construction of a new 38,400 square-meter high-standard industrial factory, and fully integrate the 10,000-square-meter production capacity of Songu Laser’s facility located in the Taicang Port Economic & Technological Development Zone, Jiangsu Province, into the Xuzhou production base, thereby achieving an efficient integration of domestic production and manufacturing resources.

After three years of infrastructure development and the installation of large-scale processing equipment, Songu Laser’s Xuzhou production base has successfully completed the Phase II construction goals in terms of production capacity, personnel configuration, plant capacity, and quality management system development. This achievement has enabled the independent control of the entire production process and quality management for large-scale laser equipment.

Starting from 31st August 2024, Songu Laser will relocate its 10,000-square-meter production base, located in the Taicang Port Economic Development Zone, Jiangsu Province, to the Songu Laser Xuzhou production base. The facility will be officially upgraded to the “Songu Laser Industrial Park”. After the relocation, the industrial park will achieve an independently controlled production capacity of 2,500 to 3,000 units (sets) of various high-end laser equipment annually.

The former “Songu Laser Suzhou R&D Center” will be relocated to the Suzhou Moon Bay International Center at 9 Cuiwei Street in Suzhou Industrial Park and will be officially upgraded to the “Songu Laser Suzhou Research Institute.” Additionally, the former “Songu Laser East China Sales and Customer Service Center” will also move to the same location and be upgraded to the “Songu Laser East China Operations Center”. This center will oversee market expansion, product sales, and customer service in Jiangsu, Zhejiang, Shanghai, and Anhui provinces, and will operate jointly with the “Songu Laser Suzhou Research institute.”

(Suzhou Moon Bay International Center)

The relocation to the Suzhou Moon Bay International Center marks the official completion of Songu Laser’s long-planned integration of resources for the research, production, and sales of metal laser processing equipment. The successful relocation of the Taicang factory signifies a major upgrade in the company’s high-quality development.

(Songu Laser Product Matrix Diagram)

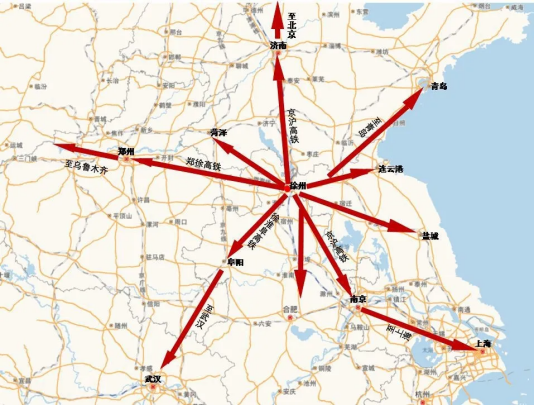

Rooted in Xuzhou, Impacting the World

Xuzhou, known as the “Capital of Construction Machinery in China”, is one of the most comprehensive regions in the country in terms of construction machinery categories and types, with some of the highest technical standards. The industrial machinery sector, one of Xuzhou’s key industries has developed over decades and is now the city’s most influential and competitive industry. It is supported by over 6,000 companies spanning fields such as R&D, parts, accessories, machinery, and services, including several global industry leaders with billion-dollar valuations. Xuzhou’s products span 20 categories of industrial machinery and nearly 1,000 models, forming a massive industrial machinery cluster and a complete supply chain system that plays a crucial role in the global large-scale equipment manufacturing market.

Xuzhou, Jiangsu Province Location Map

Founded in 2006, Songu Laser Technology (Jiangsu) Co., Ltd. (formerly known as Jiangsu Han’s Yueming Laser Technology Co, Ltd.) possesses cutting-edge technology and expertise in the designing and manufacturing of ultra-high-power 3000-watt axial fast-flow CO2 lasers, the development and production of large-scale industrial laser equipment, and the customization of automation equipment across various industries. Songu Laser has been deeply rooted in Xuzhou for 18 years, focusing on the research, production, and sales of high-end laser equipment.

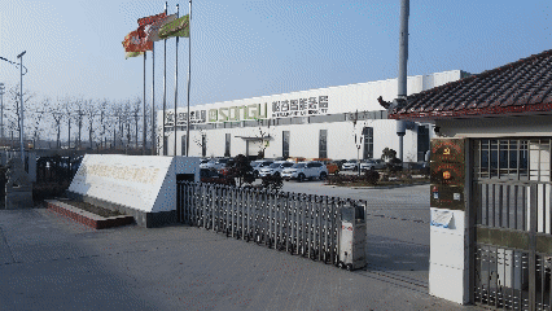

The Songu Laser Xuzhou production base covers nearly 70,000 square meters and is built on a fully digitalized, intelligent manufacturing system. It is an ultra-large, modern laser equipment manufacturing industrial park designed and constructed to the highest standards. The base has end-to-end production capabilities, from steel cutting, welding, heat-treatment, precision machining, and surface coating, to full machine assembly and testing, all with fully autonomous control and a robust quality management system. Over the years, The Songu Laser Xuzhou production base has continued to expand with a strategic focus on transformation, upgrading, and high-quality development, striving to become a world-class intelligent manufacturing industrial park and a model for the laser industry.

The second-phase expansion project of Songu Laser’s Xuzhou production base was launched in 2021, with a total expansion area of 38,400 square meters and an investment exceeding 150 million RMB. The project includes facilities such as material cutting workshops, sheet metal workshops, heavy equipment welding workshops, heat treatment workshops, sandblasting workshops, precision machining workshops, surface coating workshops, large-scale laser equipment assembly and testing production lines, and a fully automated warehouse logistics center.

To date, after more than three years of steady development, the Xuzhou base has successfully achieved the planned capacity targets for the second-phase expansion. In terms of quality system construction, Songu Laser has been at the forefront by introducing world-class systems widely used by Fortune 500 companies, such as SAP management, MES production, PLM, and modular manufacturing. This has facilitated the deep integration of new-generation information management with the company’s operational development, aligning Songu Laser with the top international quality standards.

With the successful completion of various project targets, the Xuzhou base has now evolved into a large-scale, digitally-driven industrial laser equipment manufacturing park, boasting advanced technology, strong capabilities, a talent-rich environment, comprehensive facilities, and abundant production capacity and potential.

According to the established plans for the second-phase expansion, once the Taicang factory is fully relocated and integrated into the Xuzhou production base, the annual output value is expected to easily exceed 1 billion RMB.

“Since its inception, Songu Laser has targeted replacing imported laser equipment from developed regions such as those in Europe, North America, and Japan, positioning itself as a high-end brand. Songu Laser’s product design philosophy and quality assurance system are built strictly in accordance with Europe’s highest standards.

Today , as the global manufacturing industry continues to transform, the majority of laser equipment manufacturers are fiercely competing on price, striving to sell as much as possible and seize market share.

In contrast, Songu Laser remains unwavering in its commitment to quality control at every meticulous stage of the manufacturing process. For Songu Laser, product quality is a non-negotiable corporate red line and the core competitive edge of the brand. It is also the key reason why large enterprise clients continue to choose Songu Laser.”

— Zhuo Jinsong, Chairman and General Manager of Songu Laser Technology (Jiangsu) Co., Ltd.

Global Selection of High-Quality Equipment Components, Collaborating to Build a High-Quality Supply Chain

In terms of raw materials and component procurement, Songu Laser boasts a highly efficient and resilient supply chain alliance, much like a ‘steel army’ of partner enterprises. Its suppliers include leading companies, state-owned enterprises, central enterprises, and internationally renowned firms across various industries in Europe, North America, Japan, and beyond. The company has established long-term, stable, and efficient strategic partnerships with these entities.

Songu Laser continuously optimizes its supply chain from the technical side, maintaining firm control over the research and development of key core components, driving technological innovation, and improving manufacturing processes. The company is dedicated to strengthening its quality standards system and has built a stable, reliable, and independently controlled high-quality supply chain on a global scale. This efficient collaboration with industry resources ensures the seamless connection between the procurement of supporting materials and production, powerfully guaranteeing Songu Laser’s product quality, order fulfillment capability, and highly efficient after-sales support.

Songu Laser Supply Chain Brand Matrix

Small steel manufacturers typically lack strict standards in iron ore sourcing, manufacturing processes, and process control, resulting in a significant gap compared to large state-owned steel producers. The steel used by Songu Laser for the self-manufacturing of machine tool beds is directly sourced from designated large stage-owned steel manufacturers. This steel meets the highest national standards in terms of chemical composition, mechanical properties, physical characteristics, machinability, weldability, cutting performance, climate adaptability, and impact resistance.

The steel is produced under an internationally recognized industrial quality management system, ensuring full-process traceability of steel quality. By controlling the source of steel procurement, Songu Laser effectively guarantees the exceptional quality and high reliability of every laser equipment produced. This has earned widespread recognition and praise from high-end clients worldwide.

Introducing World-Class Processing Equipment and Building a Large-Scale Digitalized High-End Laser Equipment Manufacturing Base

To stay aligned with the advanced standards of the global equipment manufacturing industry and continuously improve the quality, stability, and precision of its entire product line, Songgu Laser has made significant investments in introducing nearly 100 units of high-end industrial processing machines and various testing equipment. These include large five-axis machining centers, gantry-type machining centers, CNC lathes, CNC milling machines, and CNC grinding machines. This investment fundamentally ensures that Songu Laser's equipment achieves higher processing precision, better stability, greater overall reliability, lower wear and tear, and extended service life. By doing so, Songu Laser provides its customers with laser equipment that offers superior added value.

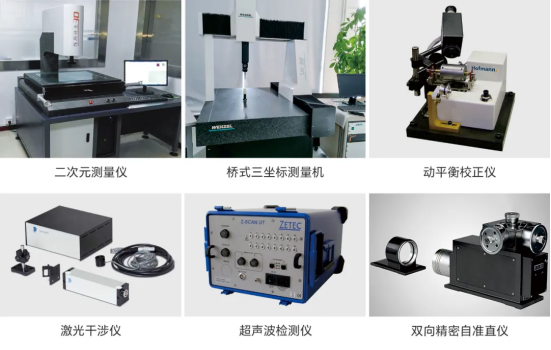

Importing High-End Testing and Inspection Equipment, Comprehensive Upgrade of the Quality Assurance System

Songu Laser has taken the lead by importing the most advanced testing and inspection equipment from industrially developed nations such as Europe, the United States, and Japan. These include coordinate measuring machines (CMM), dynamic balancing correction instruments, laser interferometers, roundness measurement machines, collimators, metallographic microscopes, ultrasonic detectors, infrared analyzers, and more.

Songu Laser’s inspection process is rigorously executed through three major stages: incoming material inspection, in-process inspection, and final product inspection. Scientific and stringent inspection procedures, standards, and technologies are applied throughout the entire process. Songu Laser has obtained numerous internationally international certifications, including ISO9001 Quality Management System certification, European TUV safety certification, EU CE certification, and U.S. FDA certification. These achievements ensures that Songu Laser delivers truly world-class craftsmanship in China’s laser equipment industry.

Partial Display of Songu Laser’s Inspection Equipment

Songu Laser’s Xuzhou production base will adhere to the company’s development plan focused on informatization, intelligence, and digitalization. Leveraging its unique advantage of fully autonomous in-house manufacturing, the company will strengthen quality control across the entire industrial chain. This will serve as a solid “Great Wall” of quality assurance for Songu Laser.

The new production base will further enhance the flexibility of autonomous production, improve the reliability of product quality, and boost the resilience of its supply chain. This will enable a visible, self-controlled product quality management model. Externally, Songu Laser will provide global customers with more convenient and professional one-stop solutions for laser equipment and its automation, intelligent systems, and digitalization support systems. These efforts will ensure mutual benefits for Songu Laser and its global partners, safeguarding the stability of product quality from the source of each process.

Following the relocation of Songu Laser’s Jiangsu Taicang production base to the Xuzhou Songu Laser Industrial Park, the new industrial park will achieve an annual production capacity of 2,500 to 3,000 sets of high-end laser equipment. The completion rate will exceed 90%. This marks a major upgrade in the integrated development and quality assurance system of Songu Laser Technology (Jiangsu) Co., Ltd., completing the transition from research to production and sales. With this upgrade, the company has successfully achieved domestic alternatives to imported laser equipment from Europe, the U.S., and Japan, earning increasing trust and praise from industry clients worldwide.

A brand-new Songu Laser is marking 2024 as the starting point for a new era of advanced productivity. Leveraging the technical strength of the Suzhou Research Institute and the robust production capacity of the Xuzhou manufacturing base, we are committed to providing global customers with cutting-edge, high-performance, and top-quality laser equipment, along with professional and efficient after-sales service. We warmly welcome new and returning customers from around the world to visit Songu Laser for exchange and collaboration!

Related news

-

Wang Jianfeng, Deputy Secretary of the Xuzhou Municipal Party Committee and Mayor, visited Songu Las

2024-10-26 14:44:10

-

Strengthening Quality Development and Fortifying the Great Wall of Quality: Songu Laser’s 2024 Quali

2024-10-26 14:44:10

-

Songu Laser’s Taicang Factory Relocation Marks a Significant Milestone in Strategic Growth

2024-10-26 14:44:10

Spanish

Spanish Portuguese

Portuguese