Laser Tube Cutting Machine: The Smart Tool of Modern Manufacturing

In the modern manufacturing industry, precise and efficient machining is the key to improving production efficiency and product quality. With the continued advancement of technology, laser tube cutting machines, as a high-precision cutting tool, show their edge and become an intelligent weapon, bringing new possibilities to industrial production.

1. Assistance breakthrough in laser tube cutting machine technology

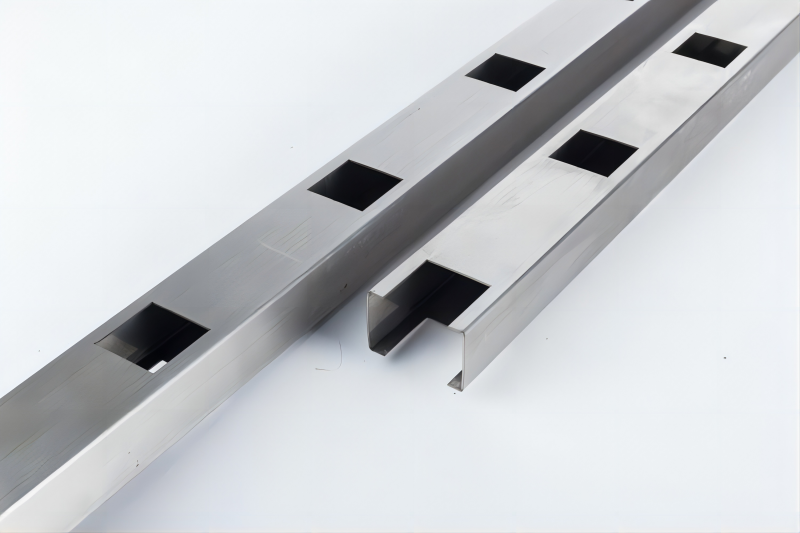

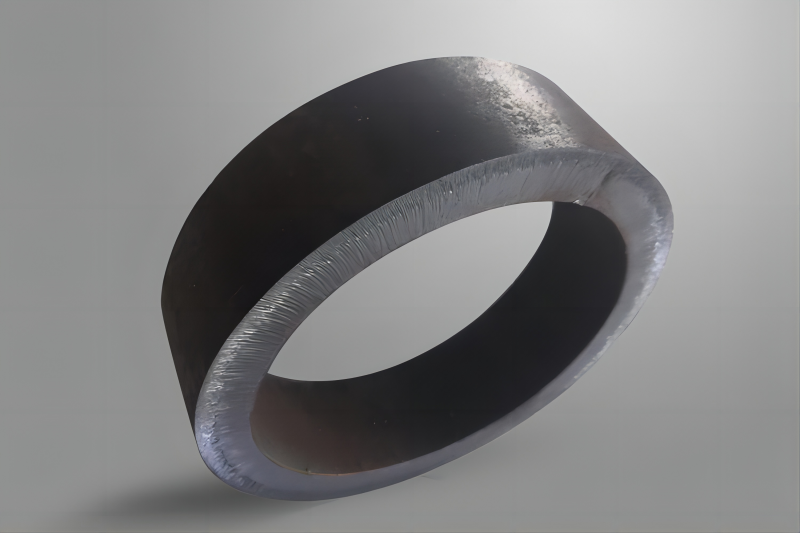

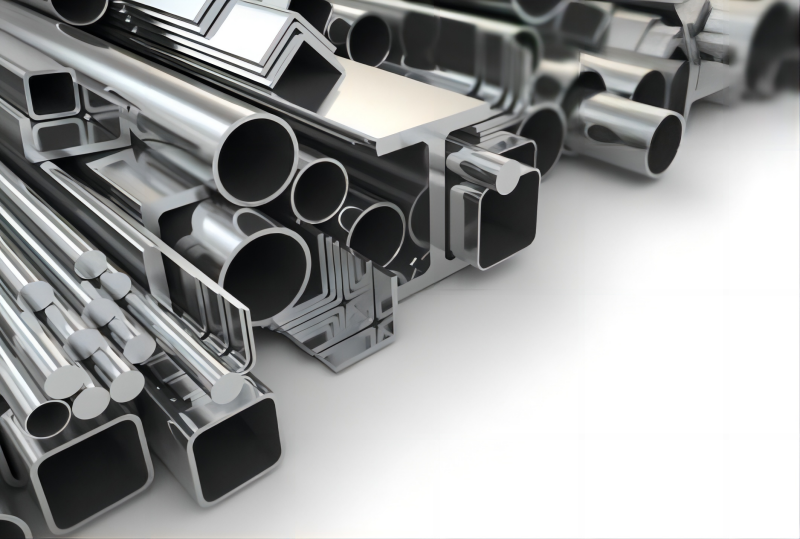

Traditional tube cutting methods typically use mechanical cutting, but this approach has certain limitations in terms of accuracy and efficiency. However, laser tube cutting machines utilize advanced laser technology to precisely cut various shapes of pipes, including round, square, oval pipes, and more. They can easily handle both simple straight cuts and complex curved cuts.

2. The advantage of laser tube cutting machine

2.1 Precision paths and high efficiency

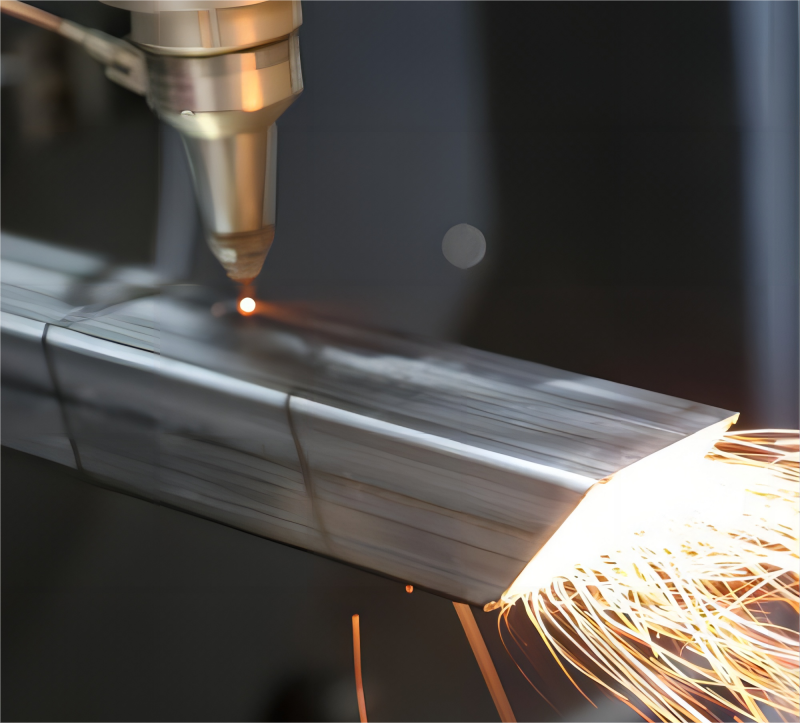

The tube laser cutting machine has excellent millimeter-level positioning and cutting accuracy, which allows for precision-level fine cutting. Compared to the traditional cutting method, it has a faster working speed and higher cutting efficiency, significantly improving production efficiency.

2.2 Automation and flexibility

The laser tube cutting machines can achieve automated production, including functions such as automatic feeding, automatic cutting, and automatic discharge. At the same time, its cutting program can be flexibly adjusted in size according to different requirements, meeting various processing needs of different shapes and pipes.

2.3 Energy saving and environmental protection

Compared to traditional cutting methods, laser tube cutting machines do not require cutting tools, reducing energy consumption and materials waste. Furthermore, laser cutting generates minimal waste, making it a more environmentally friendly option.

3. The widespread application of laser tube cutting machines

Laser tube cutting machines are widely used in construction, automotive manufacturing, aerospace, and household appliances. In the construction sector, they are used to cut various steel tube shapes to manufacture building structures. In the automotive manufacturing sector, they are used for cutting body parts and shaping components. In the aerospace sector, they are employed to cut aircraft structural parts. In the household appliance sector, they are utilized to cut pipelines for air conditioners, refrigerators, and other products.

4.Conclusion

The emergence of laser tube cutting machines has not only increased production efficiency and reduced the production cost of the manufacturing industry but also promoted the manufacturing industry to move towards a more intelligent, efficient, and environmentally friendly direction. With the continuous innovation of technology and expansion of application, laser tube cutting machines are believed to unleash their significant application value in more fields, bringing more innovative opportunities to the manufacturing industry and opening a new chapter for the manufacturing industry.

Model recommendation of laser pipe cutter:

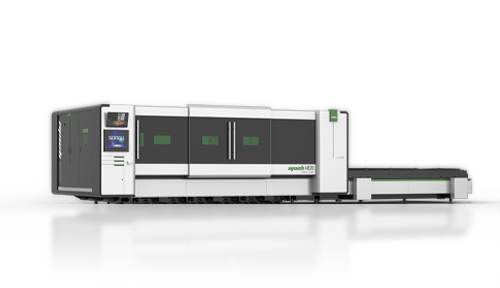

HyTube series four-chuck fiber laser pipe cutter

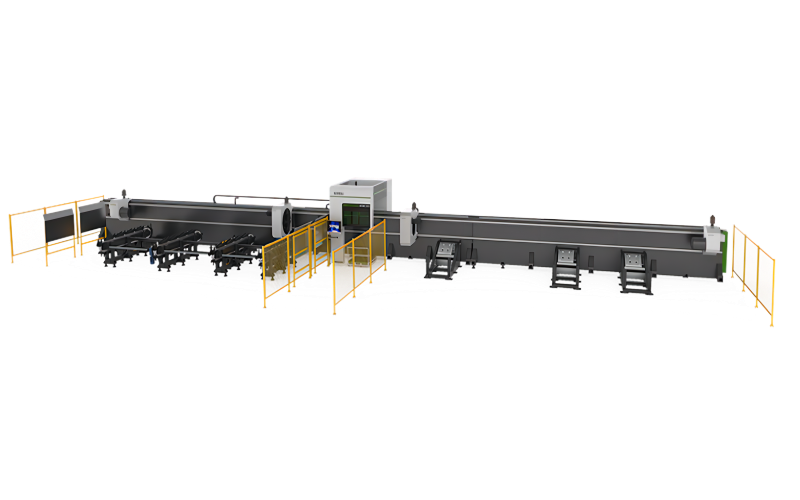

Automatic tightening of the pneumatic self-centering chuck, the clamping process does not require manual intervention, can achieve zero tailing processing, and avoid pipe waste;

Independent R&D of core numerical control system, support EtherCAT digital bus communication; built in complete cutting process database, can realize one-button setting aor real-time modification and processing according to pipe type; can be connected with MES production system to realize digital production;

Optional automatic loading and unloading device, the overall layout is compact and reasonable, the floor space is small, saving production land, reducing labor, and improving production efficiency;

Z-axis drive adopts modular drive unit, double unit, double slider design, good rigidity, light preload, effectively reduces the vibration of the cutting head during high-speed motion, and improves the accuracy of interpolation trajectory;

4-chuck structure design, the four chucks can move freely, reasonably share the weight of the load pipe stabilize the support, prevent the pipe from swinging, and ensure accurate cutting and safe cutting;

Equipped with professional pipe cutting software and built-in intelligent nesting and layout software, it is suitable for processing standard pipes, profiles and special-shaped pipes, and can realize full-time cutting high-efficiency cutting and bevel cutting.

The above is all about the manufacturing of laser tube cutting and the explanation of laser cutting technology. If you are interested in purchasing related laser equipment, feel free to consult YM laser.

Related news

-

Flexible Intelligent Manufacturing, Premium Choice! SF Series 3D Five-Axis Fiber Laser Cutting Machi

2024-01-22 12:15:08

-

Laser Empowers Clothes Hanger Intelligent Manufacturing, Defining a New Aesthetic of Balcony Fashion

2024-01-22 12:15:08

-

Laser welding helps Iron Fences enter the era of precision manufacturing

2024-01-22 12:15:08

Spanish

Spanish Portuguese

Portuguese