Laser Empowers Clothes Hanger Intelligent Manufacturing, Defining a New Aesthetic of Balcony Fashion

Smart clothes drying products with drying, lighting, disinfection, automatic lifting and other functions are becoming the first choice for young families.

The transformation from clothes drying poles and clothes drying racks to smart clothes drying machines is a microcosm of the improvement of the living standards of Chinese residents.

It also heralds the continuous development and progress of advanced processing technology represented by laser.

With the evolution of consumption upgrading, smart clothes drying machines pay more attention to the shaping of fashionable appearance. On the other hand, clothes drying machines have diverse functions, extremely complex internal structures, and very high requirements for process details in production.

More advanced and lean laser cutting and laser welding processes are replacing traditional processing methods and becoming an ideal choice for the production of smart clothes drying machines.

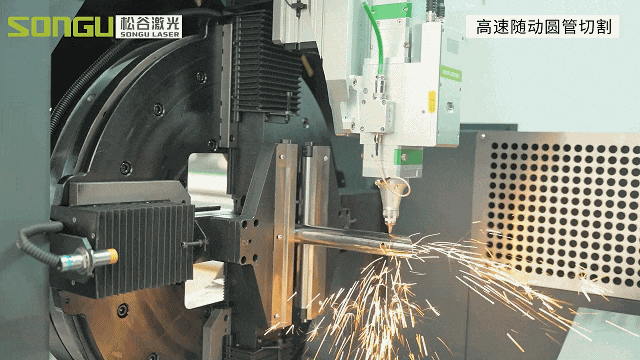

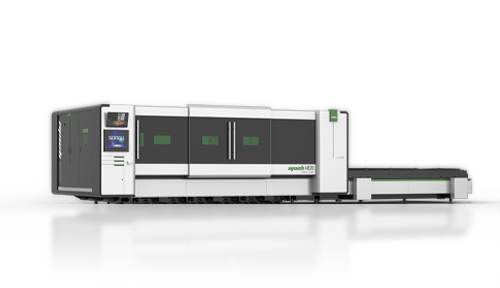

Songu laser tube cutting machine

can realize various metal tubes and profiles

fast cutting, punching, hollowing and other processing.

High processing precision, fast speed and higher flexibility.

Ensuring that each component meets the design requirements

making the design of smart clothes drying machine more diverse and innovative.

improving the overall quality and value of the product.

As a ceiling-mounted hanging device, the smart clothes drying machine is lightweight, stable, safe and flexible, which are its essential characteristics.

Songu laser welding equipment has the advantages of fast welding speed, high precision, narrow weld, good welding effect and high flexibility.

The laser welded parts have a natural welding effect, which improves the "integrity" and "stability" of the product, making the clothes drying machine more beautiful, more durable and longer life.

Laser tube cutting - machine recommendation

Tube two-chuck loading fiber laser tube cutting machine

Technical advantages

Modular design, can be freely combined and placed according to customer needs;

Upgraded self-centering full-stroke chuck, symmetrical independent double-action clamping, large clamping range;

Intelligent connection between front and rear chucks, to achieve shorter tail cutting and improve pipe utilization;

Gantry beam structure, high dynamic performance, precise positioning, high cutting efficiency;

Negative pressure suction dust removal inside the pipe and cutting area, clean and thorough;

Applicable to rectangular pipes, round pipes, waist round pipes, polygonal pipes, I-beams, angle steels and channel steels, etc.

Laser welding - machine recommendation

Continuous fiber laser welding machine

Technical advantages

The welding head structure frame can be freely selected to fully meet the differentiated requirements;

The fixture can be customized, detachable, and grafted, and can be quickly connected to the production line;

The industrial computer is used as the human-machine interaction, which is simple, reliable and easy to control;

The swing head welding can realize various types of optical path welding through the lens angle deflection;

It can realize non-contact long-distance and difficult-to-access parts. Efficient welding;

Applicable to various metals such as stainless steel, carbon steel, galvanized sheet, brass, aluminum alloy sheet, etc.

Related news

-

Flexible Intelligent Manufacturing, Premium Choice! SF Series 3D Five-Axis Fiber Laser Cutting Machi

2025-01-02 14:33:19

-

Laser Empowers Clothes Hanger Intelligent Manufacturing, Defining a New Aesthetic of Balcony Fashion

2025-01-02 14:33:19

-

Laser welding helps Iron Fences enter the era of precision manufacturing

2025-01-02 14:33:19

Spanish

Spanish Portuguese

Portuguese