Laser welding helps Iron Fences enter the era of precision manufacturing

With people's requirements for living environment becoming higher and higher, the wall, an important part of the courtyard, not only plays a role in safety protection, but more and more demands on visual aesthetics;

Due to the characteristic of metal material is flexible, strong and durable

Sun-resistant, stain-resistant, and with natural artistic texture, Metal fences have gradually become the mainstream choice

The continuous in-depth application of metal laser welding technology,

makes the design of courtyard fences more rich and novel, getting it enter the era of precision manufacturing.

Welding is a key link in the production of iron fences. Traditional welding methods, due to high mechanical pressure and high heat output, can easily cause uneven welds on the workpiece, weld nodules, weld spots, weld slag and other undesirable phenomena, and even cause deformation of the workpiece, which not only greatly reduces the beauty of the iron fence, but also bury safety hazards for long-term use.

The shapes of wrought iron fences are complex and varied. The shapes are either curved or straight. With complex and varied metal decorations, these complex workpieces are perfectly spliced and inlaid with each other through fine and flexible laser welding technology. Finally, a perfect wrought iron fence is presented, forming an elegant and beautiful courtyard landscape.

Laser, as a new generation of welding method, it has fast welding speed and high precision. It can achieve ultra-fine welding. The heat-affected area is small during welding, without deforming the workpiece. The welding surface is smooth and free of residue and dust. The laser welding equipment is intelligent and easy to learn and use. You can start welding with simple training, without professional welders. It greatly reduces the operator threshold and helps companies reduce labor costs.

Laser welding-Model Recommendation

- SG-A Handheld Laser Welding Machine -

Technical advantages

▷ Integrated design saves space and can be flexibly placed, moved and carried;

▷ Adopt lightweight handheld laser head, red light positioning, automatic gas control, simple operation;

▷ Four functions: welding, cleaning, weld cleaning and cutting, 4 in 1 machine for multiple uses;

▷ Professional control system, flexible parameter setting, built-in process library, easy to learn and use;

▷ Fully automatic wire feeder, compatible with 0.8-1.6mm welding wire, with a wider range of applications;

Related news

-

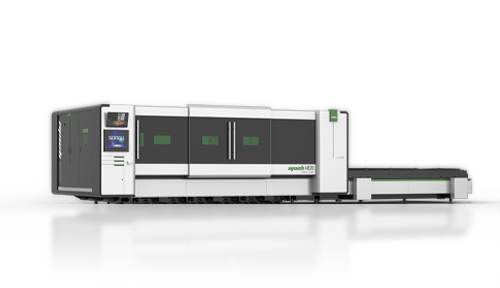

Flexible Intelligent Manufacturing, Premium Choice! SF Series 3D Five-Axis Fiber Laser Cutting Machi

2025-01-01 14:26:19

-

Laser Empowers Clothes Hanger Intelligent Manufacturing, Defining a New Aesthetic of Balcony Fashion

2025-01-01 14:26:19

-

Laser welding helps Iron Fences enter the era of precision manufacturing

2025-01-01 14:26:19

Spanish

Spanish Portuguese

Portuguese