Aluminum Alloy Laser Welding: The Fantasy Fusion Of Light And Metal

In modern engineering and manufacturing, there is one technology that is controlling outcrops at breakneck speeds: melt laser welding. This magical technology, like a fantastical fusion of light and metal, creates an incredible miracle of manufacturing. This will allow you to enter this fascinating fantasy world and discover the wonders of laser welding.

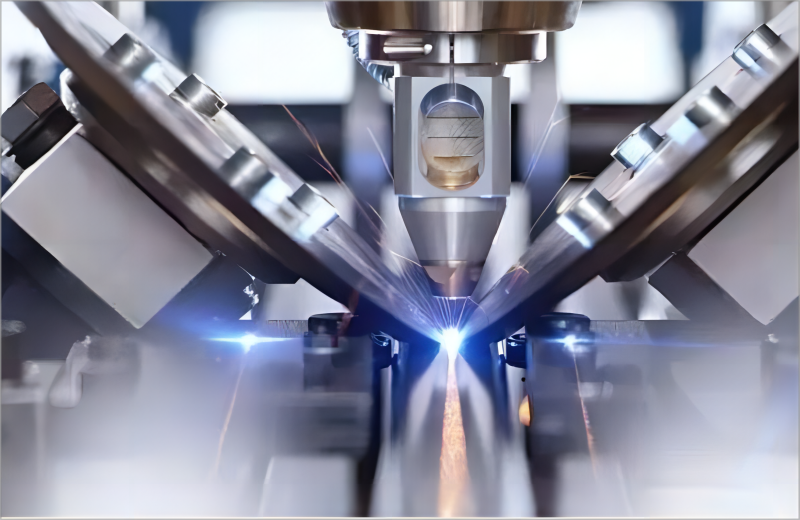

Laser light

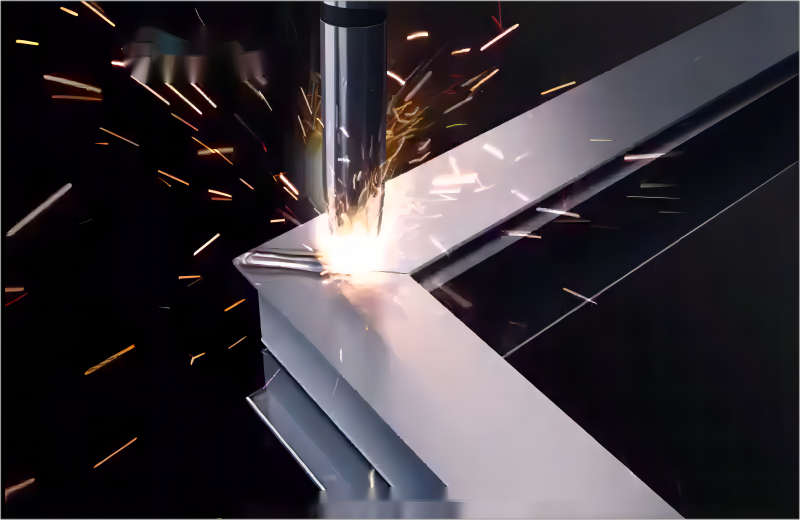

The magic of aluminum alloy laser welding comes from laser light. Laser is a highly concentrated beam of light, which can accurately focus energy on the surface of the aluminum alloy and create a heat zone. This beam, just like a magical lightsaber, is able to melt in a instant for precise and robust welding.

The Art of welding

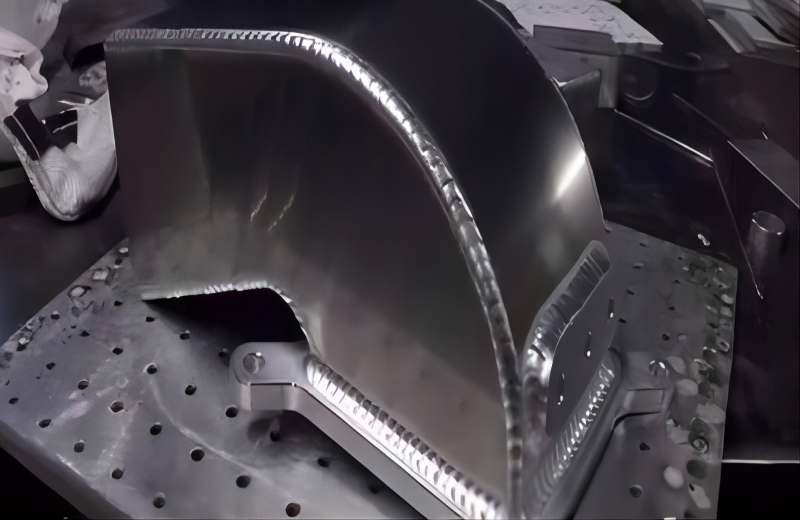

Aluminum alloy laser welding not just a science, but also an art of welding. This technology can achieve high level welding and guarantee the strength and tightness of welding point. Each welding is a precision performance, just like an artist creating a masterpiece. This exquisite art enable Aluminum alloy welding to play an unmatched value in the fields of aerospace automotive industry and electronics manufacturing.

Future magic

In the future, aluminum alloy welding will continue to exert its magical power. With technology development, we can expect more intelligent and adaptive laser welding system which can adjust in real time according the characteristics and design requirement of different aluminum alloy. It will improve the precision and efficiency of welding and make welding more intelligent.

Aluminum alloy laser welding forging more materials in the welding field, including complex multi-material combinations. This will promote the application of aluminum alloy materials from automotive manufacturing to electronics to construction. In the end, the welding technology will also focus on environmental protection and sustainability. In the future, the welding technology will focus more on energy efficiency, using more energy efficient laser sources and reducing replace generation, resulting in meeting environmental requirements。

In short, aluminum alloy laser welding is a magical technology, which brings extremely possibilities for application and innovation of aluminum alloy materials. Whether it’s in aerospace or in our life, aluminum alloy laser welding has created lighter and stronger products for us, it is an efficient and fascinating welding magic!

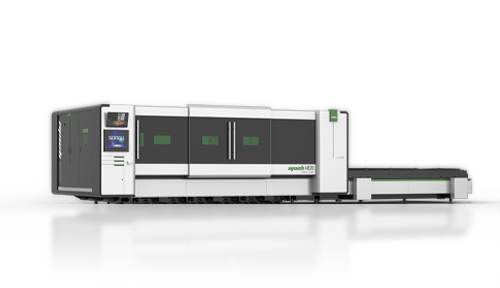

Aluminum laser welding model recommendation:

HW-D handheld laser welding machine

The whole machine is designed with an integrated structure, and the equipment occupies a small space. It is equipped with large-sized universal casters for easy carrying and handling.

The electrical control area is equipped with a cooling fan as standard, effectively improving the welding stability in high-temperature environments (optional cabinet air conditioning).

Equipped with a variety of welding conductive nozzles as standard, it meets various welding needs and can achieve high-precision welding with small, beautiful and firm welds.

Visualization instruments and water injection ports can be used to observe the usage process at any time. At the same time, a touch screen control panel is used to make modifying process parameters more intuitive and convenient.

Professional laser welding software with powerful functions, easy to learn and use, can be used after general training, without the need for professional welders.

Energy saving and environmentally friendly, with a total power consumption of less than 7 kWh per hour and no other consumables, suitable for industries such as sheet metal, automotive parts, furniture, advertising, etc.

The equipment has strong scalability and can be connected to wire feeders, robots, etc. It can be optionally equipped with single or double swing welding heads.

The system can store various process parameters, and according to processing requirements, it can be switched at any time through the touch screen, significantly reducing parameter debugging time.

Thank you for your interest! Songu Laser has always been committed to providing excellent laser solutions for our customers. We use advanced technology, excellent quality and professional team to escort you and add to the innovation of various industries. By choosing Songu Laser, you are not only choosing the leading technology, but also choosing a reliable partner. Any questions or needs, please feel free to contact our official service hotline: 86-13925892493, we look forward to providing you with the best laser solutions!

Related news

-

Flexible Intelligent Manufacturing, Premium Choice! SF Series 3D Five-Axis Fiber Laser Cutting Machi

2024-04-01 14:29:55

-

Laser Empowers Clothes Hanger Intelligent Manufacturing, Defining a New Aesthetic of Balcony Fashion

2024-04-01 14:29:55

-

Laser welding helps Iron Fences enter the era of precision manufacturing

2024-04-01 14:29:55

Spanish

Spanish Portuguese

Portuguese